We understand the importance of engineering designs, reviews, and approvals. As there was no previously established or industry accepted design philosophy or equation to define shotcrete liners installed on existing culverts, we worked with a third-party engineering firm to build a program to ensure the future performance of all work done by National Gunite.

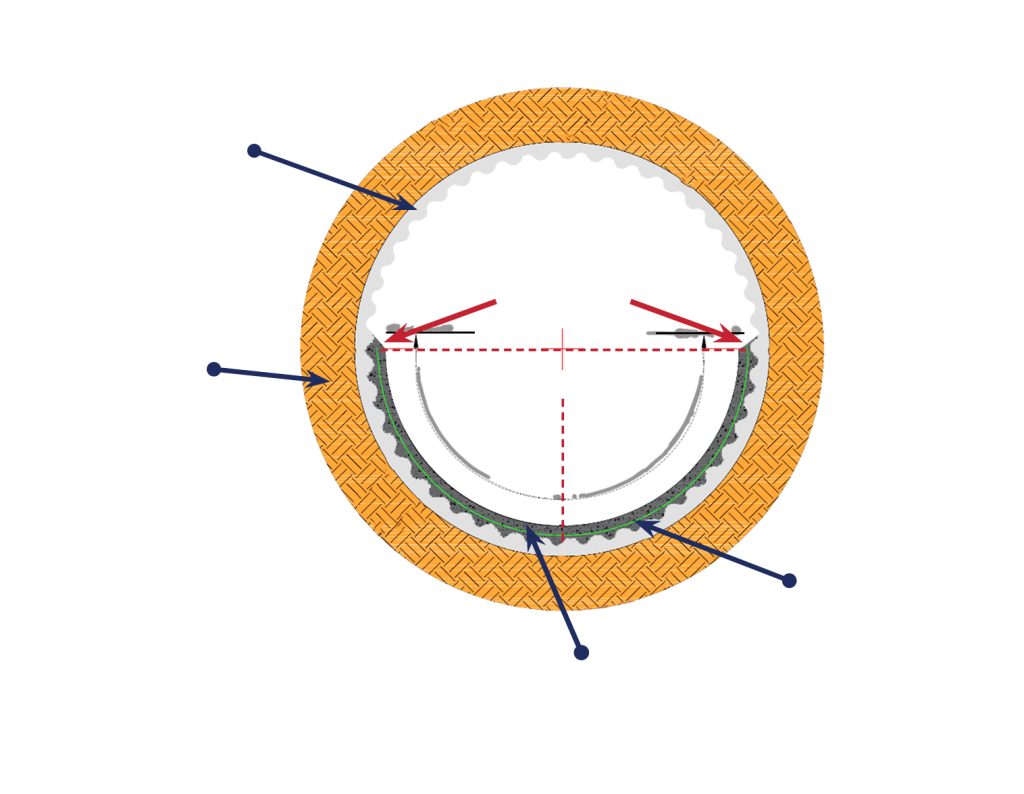

National Gunite’s Customized Pipelining Design Program takes user input on the type, size, and structural makeup of the conveyance system and the geotechnical constraints for the surrounding soil conditions then iterated on coating thickness and reinforcement per foot to provide the optimized and most economical structural design for the repair. The design equations assume zero strength of the existing structure and are based on concrete pipe design with a flexibility factor applied for applications onto corrugated metal piping.

With National Gunite’s quality craftmanship and custom designs engineered for your project, you can have the confidence that you are investing in a fully structural solution that is not overdesigned nor under designed.

- Thickness

- Microsilica Additives

- PSI Strength

- Water Flow

- Rebar Material

- Gauge of Wire Mesh

- Spacing

- Depth of Cover

- Highway Traffic

- Parking Lot

- Linear Footage

- Invert Condition

- Crown Condition

- Pipe Material

- Diameter

- Pipe Age

- Existing Subgrade

- Backfill Material

- Depth of Pipe

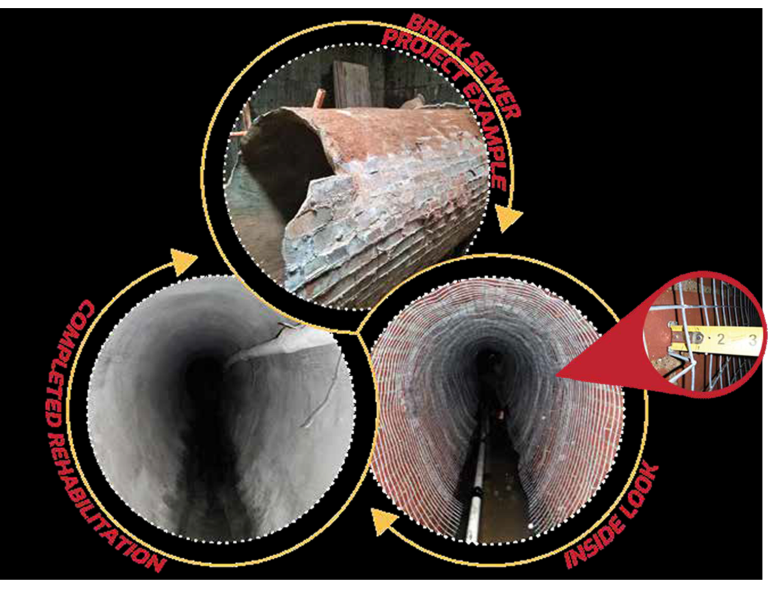

Fully Structural Rehabiliation using merely 2” of structural Gunite with 2” x 2” 12-gauge welded wire mesh reinforcement added.

Several days after the sewer was structurally rehabiliated, the Prime Contractor, using pneumatic chipping hammers, chipped off all the brick from the outside of the sewer leaving the fully structural Gunite in place (top picture). Internal bypass was achieved by running rigid PVC through the invert (botton right) when lining the crown and sides of the pipe. Bypass was then hung fom the side of the pipe (bottom left) while structurally lining the Invert.

Concrete, brick, and metal pipelines deteriorate over time, causing leaks, sinkholes, and cave-ins. National Gunite provides trenchless repair of sewers and storm culverts using concrete that is pneumatically sprayed onto steel reinforcement. We can repair these lines from inside the pipe by lining the pipe with steel reinforcement and spraying the surface with multiple inches of shotcrete. The finished repair fully restores the structural integrity of the pipe for decades of future use.

control & Bypass Water Flow

National Gunite will dewater the work area within the confines of the pipe by constructing a temporary sandbag weir and directing the flow through an internal flume system. On rare occasions, external bypass pumping may be necessary.

Clean Debris & Prepare the Pipe

Our crew cleans and prepares the interior of the pipe. Light and heavy debris is removed either by hand or mechanically. If necessary, deteriorated/rusted sections of pipe may be removed by using cutting blade grinders and/or pneumatically powered saws.

Install Steel Reinforcement

Reinforcement could range from fibers (added while mixing shotcrete materials) to rebar. Typical reinforcement consists of galvanized steel wire mesh, but depends on the pipe design parameters of our program.

Shotcrete Application

National Gunite applies micro-silica enhanced dry-mix shotcrete (aka Gunite) typically from the 3 to 9 o’clock position on the pipe. Micro-silica increases strength and enhances resistance to abrasion, as well as corrosion.

Restore Water Flow

Typically 12-16 hours after the final application of shotcrete, the temporary sandbag weir is removed and the water is restored through the structurally rehabilitated pipe.

National Gunite’s key to success are the trusted relationships we have built with our customers. Service doesn’t end when the project is completed.